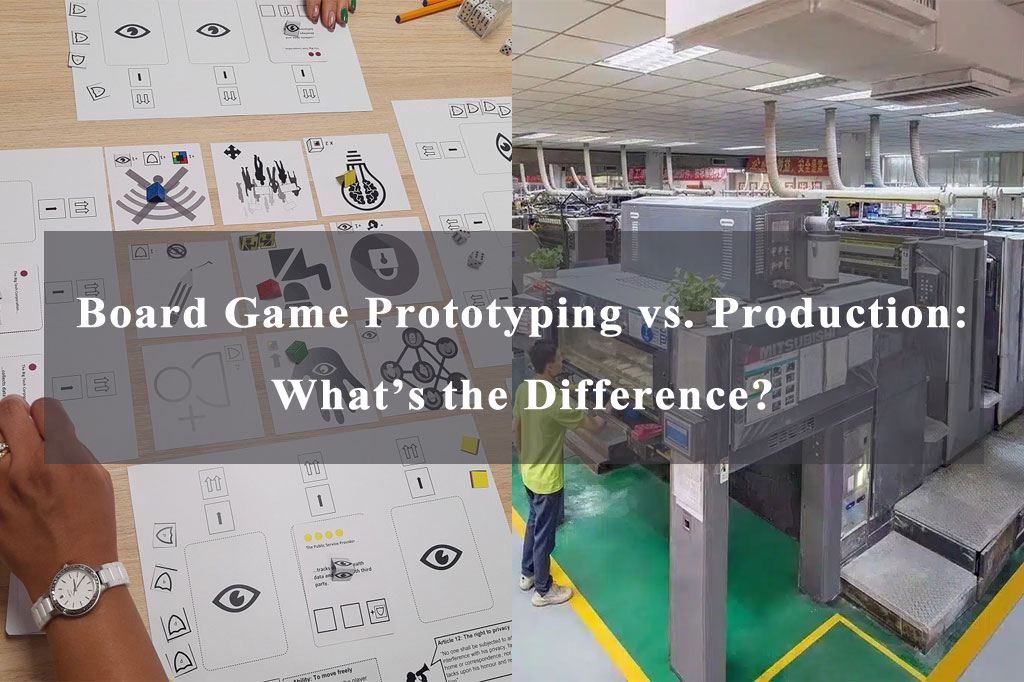

For first-time developers and even experienced game creators, understanding the distinction between board game prototyping and mass production is crucial to bringing an idea to life effectively and efficiently.

While both stages are essential in the development process, they serve very different purposes, require different resources, and involve different timelines and expectations.

Here’s a quick summary of their differences:

| Aspect | Prototyping | Production |

|---|---|---|

| Purpose | Testing and refining | Manufacturing the final product |

| Materials | Temporary, flexible | Durable, high-quality |

| Cost per Unit | High | Low at scale |

| Quantity | 1 to 10 units | 300 to 10,000+ units |

| Timeline | 3 – 7 days | 30 – 45 days |

| Design Requirements | Placeholder art acceptable | Print-ready files required |

| Goal | Gather feedback | Distribute to customers |

Table of Contents

1. Purpose and Goals

Prototyping: Testing and Refining

The primary goal of prototyping is to test gameplay mechanics, visual design, and user experience. A prototype is a work-in-progress version of your board game used to gather feedback from playtesters, revise rules, refine balance, and improve the overall experience.

Prototyping allows designers to answer questions such as:

- Is the game fun and engaging?

- Are the game rules easy to follow?

- Is the game balanced and replayable?

Production: Delivering the Final Product

Production, on the other hand, focuses on manufacturing the final version of your board game at scale. This stage comes only after extensive testing and refinement during prototyping. The production process aims to create a professional-quality product ready for distribution, sale, or Kickstarter fulfillment.

The focus here is on:

- Quality consistency

- Efficient logistics

- Scalability

- Cost-effectiveness per unit

2. Materials and Components

Prototyping: Flexible and Temporary

Prototypes often use basic materials that simulate the final components but don’t match them in quality. These may include:

- Inkjet or laser-printed cards

- Handmade or laser-cut tokens

- Simple blank dice with stickers

- Custom game boards made from cardboard or chipboard

- Generic meeples or figures

Prototypes are often built quickly, and they evolve with each testing round. It’s common to create multiple versions with slight variations to compare gameplay outcomes.

Production: High-Quality and Durable

On the other hand, production materials are chosen for their strength, visual quality, and suitability for retail.These include:

- Offset printed cards with professional coatings

- Injection-molded plastic miniatures or custom tokens

- Game boards with linen finish and sturdy construction

- Retail-quality packaging

- Finishing options like foil stamping, UV coating, embossing

Consistency is critical in production. Every unit must be nearly identical, both in quality and appearance.

3. Costs and Quantities

Prototyping: Low Volume, Higher Unit Cost

Prototypes are typically produced in small batches – anywhere from a single copy to a few dozen for blind playtesting or early previews. The cost per unit is usually higher due to manual labor, short-run printing, or use of prototyping equipment.

For example, a single prototype might cost $50 – $150, depending on complexity. However, this cost is considered an investment in development, iteration, and improvement.

Production: High Volume, Lower Unit Cost

Production involves bulk manufacturing – usually starting at 300 to 1000 units, with large-scale campaigns producing 10,000+ copies. While the initial investment is substantial (ranging from a few thousand to tens of thousands of dollars), the unit cost drops significantly at scale.

Board game manufacturers often provide tiered pricing, where the cost per game decreases as the order quantity increases.

4. Timeline

Prototyping: Quick Turnaround

Prototyping timelines are shorter, especially when working with digital print services or prototyping-focused manufacturers. Depending on complexity, you can often get a prototype in 3 – 7 days.

This fast turnaround is ideal for iterative testing, allowing you to revise and retest efficiently.

Production: Longer Lead Times

Production timelines are significantly longer. Once files are finalized and approved, the typical process includes:

- Pre-production samples and approval (3 – 5 days)

- Mass manufacturing and packaging (5 – 10 days)

- Shipping and logistics (20 – 30 days depending on location)

In total, you should expect the production process and shipping time to take 30 – 45 days.

5. Design and File Requirements

Prototyping: Flexible Design

Prototype designs don’t need to be perfect. You can often use placeholder art, hand-written cards, or simple layouts. The focus is on function, not form.

Some creators even make homemade prototypes using a printer, scissors, and basic crafting tools to minimize costs and maximize flexibility.

Production: Print-Ready Files

Production requires finalized, print-ready artwork. Files must follow strict guidelines, including:

- CMYK color mode

- Correct bleeds and margins

- Vector die lines

- High-resolution images (300 DPI+)

- Converted fonts or outlined text

Many game producers provide templates and design guidelines to ensure everything is prepared correctly.

6. Feedback vs. Fulfillment

Prototyping: Internal Feedback

During prototyping, the feedback loop is critical. You’re not creating a finished product; you’re building a system to learn what works and what doesn’t. Playtesters may report unclear rules, broken mechanics, or even thematic inconsistencies.

You’ll often revise your prototype multiple times before moving to the next stage.

Production: Ready for Fulfillment

Once in production, the feedback process ends, and you shift focus to logistics, storage, and fulfillment. You may need to:

- Work with a fulfillment partner

- Handle backer shipments (if crowdfunding)

- Prepare for retail or distribution

At this stage, the game is finished, and your role becomes more about delivery and customer support.

7. Working with a Manufacturer

Some manufacturers offer both prototyping and production services, which can streamline your process and ensure consistency. It also allows for a smoother transition when you’re ready to move from testing to mass manufacturing.

Look for a manufacturer that can:

- Help with file setup and templates

- Provide quick prototype services

- Offer competitive bulk pricing

- Support custom components

- Handle packaging and shipping